RSHS

LYE

LATEX

Mineral

Oils

Mayonnaise

Maize

Adhesive

Chocolate

Dowtherm

Edible Oil

Emulsion

Enamel

F.O.

Formaldehyde

Fats

Fatty Acid

Glycol

Hydraulic Oil

H.F.O.

Honey

Insecticides

Lacquer

L.D.O.

Lube Oil

Paraffin

Printing ink

P.U. Foam

Plasticizers

Peanut Butter

Resins

Starch & Syrup

Sodium Silicate

Soap

TAR

Varnish

Viscose

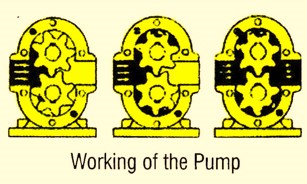

The simplified in and around flow design of UNIQUE Rotary pump permits easy handing of wide range of Viscosities and minimizes internal loss. Unique rotary pump is engineered for superior performance and longer life.

Hardened Gears provide a longer gear life and quiet pulsation free flow. the helical configuration offers greatest face area for strength. Precision machined teeth engage gradually preventing trapping of liquid which absorbs shocks. Full hydraulic balance eliminates need for specialized balancing devices or thrust bearings.

Bearings are internal, set close to the load. this short bearing span, combined with a short, stocky shaft, handles high pressure with minimum deflection. Force - feed lubrication by the pumped liquid results in less leakage and no contamination by the lubricant and eliminates the need for a separate lubrication system.

CAPACITIES : 2to6000LPM

PRESSURE : UPT0 70 kg / cm

VISCOSITIES : UPTO 1,00,000 CSTSPEED : 50 to 1500 R.PM

Body & Covers : Mild Steel, Stainless Steel, Gun Metal, Cast Iron, Bronze, Super Alloys

Shaft & Gears : Carbon Steel, Stainless Steel, (Hardened and Profile ground gears if necessary)

Shaft Sealing : Oil Seal, Mechanical Seal, Gland Packing

Bearing : Steel Antifriction, Bush Bearings (G.M., Bronze, Carbon, Teflon)

| Model No. | Suction X Delivery Size | Capacity Range LPM | Std. Pump Speed RPM |

|---|---|---|---|

| UA-5 | 3/8" x 3/8" | 2 To 5 | 1440 |

| UA-10 | 1/2" x 1/2" | 6 to 20 | 1500 |

| UA-15 | 3/4" x 3/4" | 21 to 30 | 1500 |

| UA-15SP | 3/4" x 3/4" | 31 t0 50 | 1500 |

| UA-20 | 1" x 1" | 51 t0 75 | 1500 |

| UA-25 | 1 1/2" x 1 1/2" | 76 t0 100 | 1500 |

| UA-25 SP | 1 1/2" x 1 1/2" | 101 t0 160 | 1500 |

| UA-50 | 2" x 2" | 161 t0 225 | 1500 |

| UA-50 SP | 2 1/2" x 2 1/2" | 226 t0 350 | 1500 |

| UA-100 | 3" x 3" | 351 t0 550 | 1500 |

| UA-100 SP | 3" x 3" | 351 t0 750 | 1500 |

| UA-200 | 4" x 4" | 751 t0 1200 | 1500 |

| UA-400 | 4" x 4" | 1201 t0 1800 | 960 |

| UA-600 | 6" x 6" | 1801 t0 2500 | 960 |

| UA-800 | 8" x 8" | 2501 t0 6000 | 720 |

With higher viscosities pumps are operated at lower speeds

General recommendations of speed are as under

| Viscosities Range In Cst | Pump Speed (RPM) |

|---|---|

| UP-400 | 1440 |

| 400 to 1000 | 960 |

| 1000 to 3500 | 720 |

| 3500 to 10000 | 500 |

| 10000 to 50000 | 200-300 |

| 50000 & above | Please Consult |

| Without Pressure Relief valve | Type UA |

| With Pressure Relief Valve | Type UAV. Protect system from discharge line obstruction |

| Mechanical Seal | Type UAM. Positive Sealing/ Minimum Leakage. Packed pump can be retrofitted. |

| Flange Mounted | Type UAF. Provide vertical mounting facility |

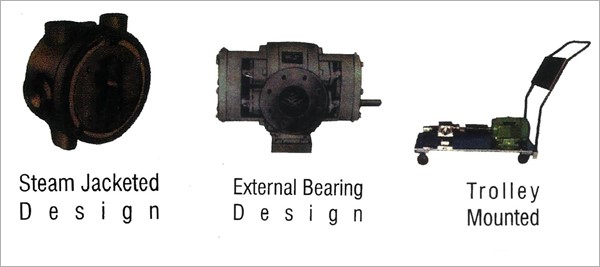

| External Bearing | Type UAX. It is an externally lubricated pump recommended for use where the liquid to be transferred does not contain any lubricating properties. |

| Stem jacketed Type | UASJ. Specially for liquids which solidify or become highly viscous at Room temperature like RSHS, FO, HFO, HHS, Glucose, Soap stock, high Viscosity Oils, Wax, Grease, Coal Tar, Bitumen, Adhesives etc. Steam circulating in the pump body to heat the liquid being pumped |

| Higher Pressure | UAHP. By providing highly precision profile ground gear high pressure up to 70kg/cm can be developed. |

| Stainless Steel | UAS & UASS. For food product & liquid which react with CI & other maintenance |

| Stainless Steel | UAS & UASS. For food product & liquid which react with CI & other maintenance |

| Custom Designed Pumps | To meet special requirements. |

Pressure, Capacity & Efficiency Curve

Input B.H.P. pump, can be calulated by following formula

BHP (Rated) = Work Done

-----------

Constant x Efficiency

Q = Capacity in m3/hrx Pressure in

kg/cm2

---------------------------------

27 (Hydraulic Constant) x Efficiency

Built in pressure relief valve is provided in pumps to operate at higher than rated pressure ie. it starts operating at 1 kg / cm higher than rated pressure and fully opens at 20 % higher than rated pressure, taking maximum 30 % higher power than rated power.

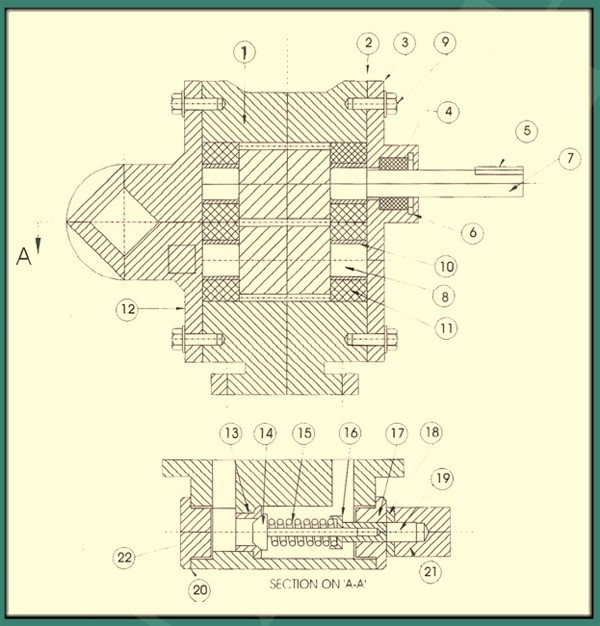

| Part no. | Description | Qty |

|---|---|---|

| 1 | Main Body | 1 |

| 2 | Packing | - |

| 3 | Front Cover | 1 |

| 4 | Oil Seal | 2 |

| 5 | Key | 1 |

| 6 | Circlip | 1 |

| 7 | Driven shaft with gear | 1 |

| 8 | Driven shaft with gear | 1 |

| 9 | Bolt with spring washer | 8 |

| 10 | Sleeve Bush / Bearing | 4 |

| 11 | Wear plate | 4 |

| 12 | Back Cover | 1 |